A good cultivation process is essential for consistent quality.

Mushrooms grow on compost. The compost is prepared by specialised companies. From the moment the raw materials are mixed until the compost is delivered to the production nurseries, it takes four to six weeks. The exact time depends on the raw materials and the system of the composting company.

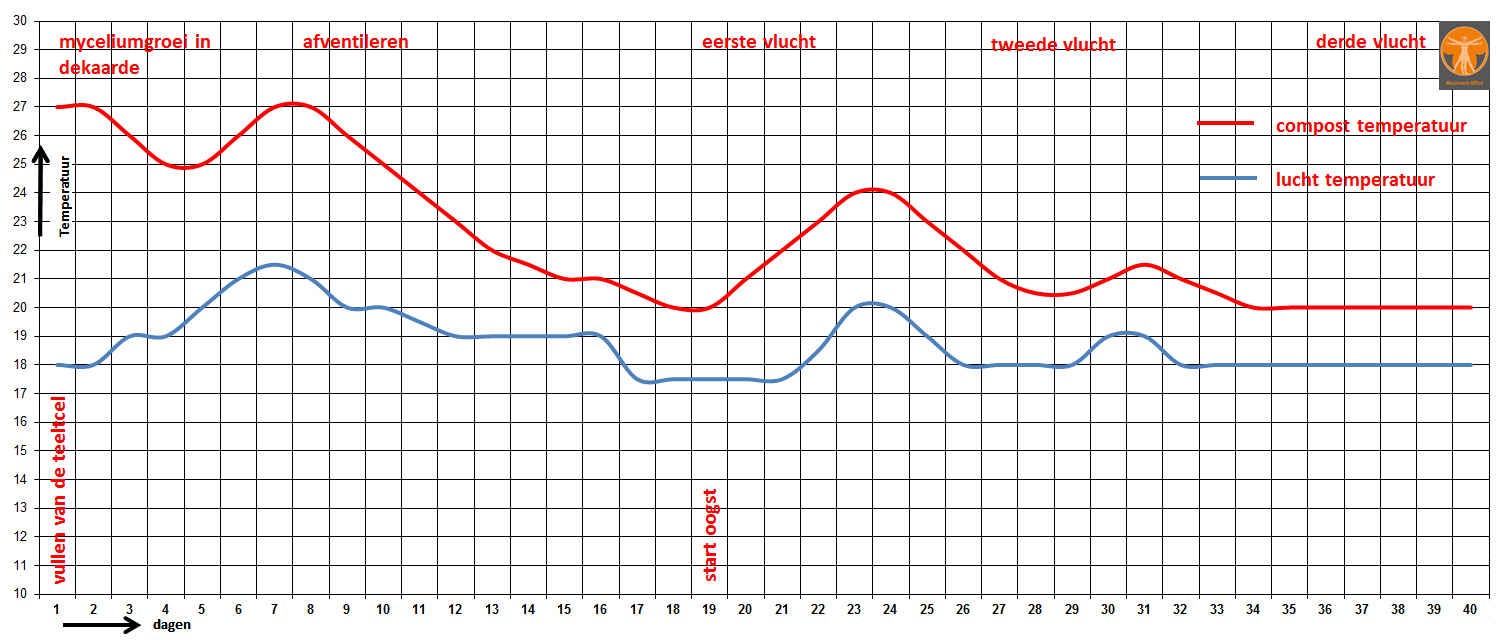

Once the compost is applied at the production site, it takes about 16 to 20 days before mushroom harvesting can begin. Harvesting takes place over two to three weeks. After that, it is no longer profitable to continue harvesting.

1. Filling the cell

After 14-18 days, the compost is transported to the farm. At the farm, the cultivation cell is filled with compost using a special filling machine. A cultivation cell is an air-conditioned room with shelves. During filling, the compost is placed in a layer of 20 cm with a layer of 5 cm casing soil on top of the compost. This layer is pulled into the shelf of the cultivation cell. Casing consists of a mixture of peat, mixed by specialised companies. At farms who do their own phase III, the compost remains in the cell, but after 14-18 days a layer of casing is placed on the compost. A cultivation cell is a climate-controlled room with shelves.

A cultivation cell is a climate-controlled room with shelves.

2. Mycelium growth in the casing

After filling the cell, the mycelium will grow from the compost into the casing. This process takes 4-7 days. During mycelium growth in the casing, water is added to the casing. By watering in the mycelium growth phase, the mycelium cannot grow to the surface of the casing.

3. Recovery Growth

After mycelium growth in the casing, the recovery growth phase takes place. This phase lasts 1 to 2 days. In the recovery phase, no water is given, and a humid, warm climate is created (similar to summer). Due to this climate, the mycelium grows to the surface of the casing.

4. Venting & Bud Formation

When the mycelium has grown to the surface, the grower starts ventilating. Ventilating is mimicking autumn. Due to colder air and lower CO2, the fluffy mycelium starts to contract. If the mycelium has contracted, it forms buds after about 5-6 days of venting. These buds (the size of pinheads) are the primordia of the mushroom. This period is called bud formation. After that, Relative Humidity (RH) in the cell is slowly lowered, so that the buds start to grow into mushrooms. From bud to harvestable mushroom takes 5 to 7 days.

5. Harvesting Phase

The harvesting of mushrooms goes in “flights.”

- The first flight is picked in 4 to 5 days and yields 16 to 20 kg/m2.

- The second flight comes after about 5-7 days and yields a slightly lower volume, 9-11 kg/m2.

Total yield is between 26 and 32 kg/m2.

During the harvest, the mushroom is sorted into the correct packaging and weighed. This is to perform as few actions as possible that may damage the mushroom.

Total yield is between 26 and 32 kg/m2.

6. Emptying the cultivation cell

At the end of cultivation, the cultivation area and the used-up compost are heated throughout. This is done using steam, in order to kill all diseases and pests. After this final pasteurisation, the compost is removed from the cell, the cell is then cleaned and can then be used for starting a new cultivation cycle.

7. Quick-cooling Mushrooms

After harvesting, the mushrooms are brought to the quick-cooling area where the temperature is reducedfrom +/-13 degrees to +/-3 degrees within 45 minutes. This benefits the quality of the mushroom; they can then be packed immediately. If a mushroom is packaged while warm, this can cause condensation on the underside of the lid or foil.

8. Packaging

During packaging, the mushroom trays are placed on the infeed conveyorof the packaging line. The tray is then checked for weight by means of a checkweigher. At the correct weight, the tray is fed to the packaging machine. During this transit, the trayundergoes a visual inspection, after which it is provided with a lid, (top) seal or foil with a label with all the necessary information.

9. Transport

The packed mushrooms then standready in the cold store to be transported to, for example, distribution centres, transshipments, markets or directly to stores. Geurts Champignons Milheeze delivers both nationally and internationally. So, our transport also crosses borders!